Armor AP

Step Up Your Game

Better Tear Strength, As Received*

Better Tear Strength, After UV*

*Compared to competitive Nomex/Kevlar Outershells

For the last two decades, fire departments choosing outer shells made of 40% DuPont™ Nomex®/60% DuPont™ Kevlar® have been limited to stiff and uncomfortable gear... until now.

Utilizing the groundbreaking Filament Twill Technology™ used in PBI Max™, Safety Components is launching Armor AP™ to fill the needs of firefighters who prefer improved mobility, improved durability, and improved protection at an economical price. Armor AP—a 6.5 oz. outer shell with absolute performance.

Specifications

Weight: 6.5 oz.

- 80% Meta/Para-Aramid spun yarns

- 20% 400 denier DuPont Kevlar filament

Overall Blend: 35% Meta Aramid and 65% Para Aramid

Weave: Comfort Twill with Filament Twill Technology

Color: Gold, Khaki, Black

The Largest Metro Fire departments have trusted in the Armor AP design through the years...below are just a few:

Chicago

Memphis

Miami

St. Louis

Sacramento (Sac Metro)

Winnipeg

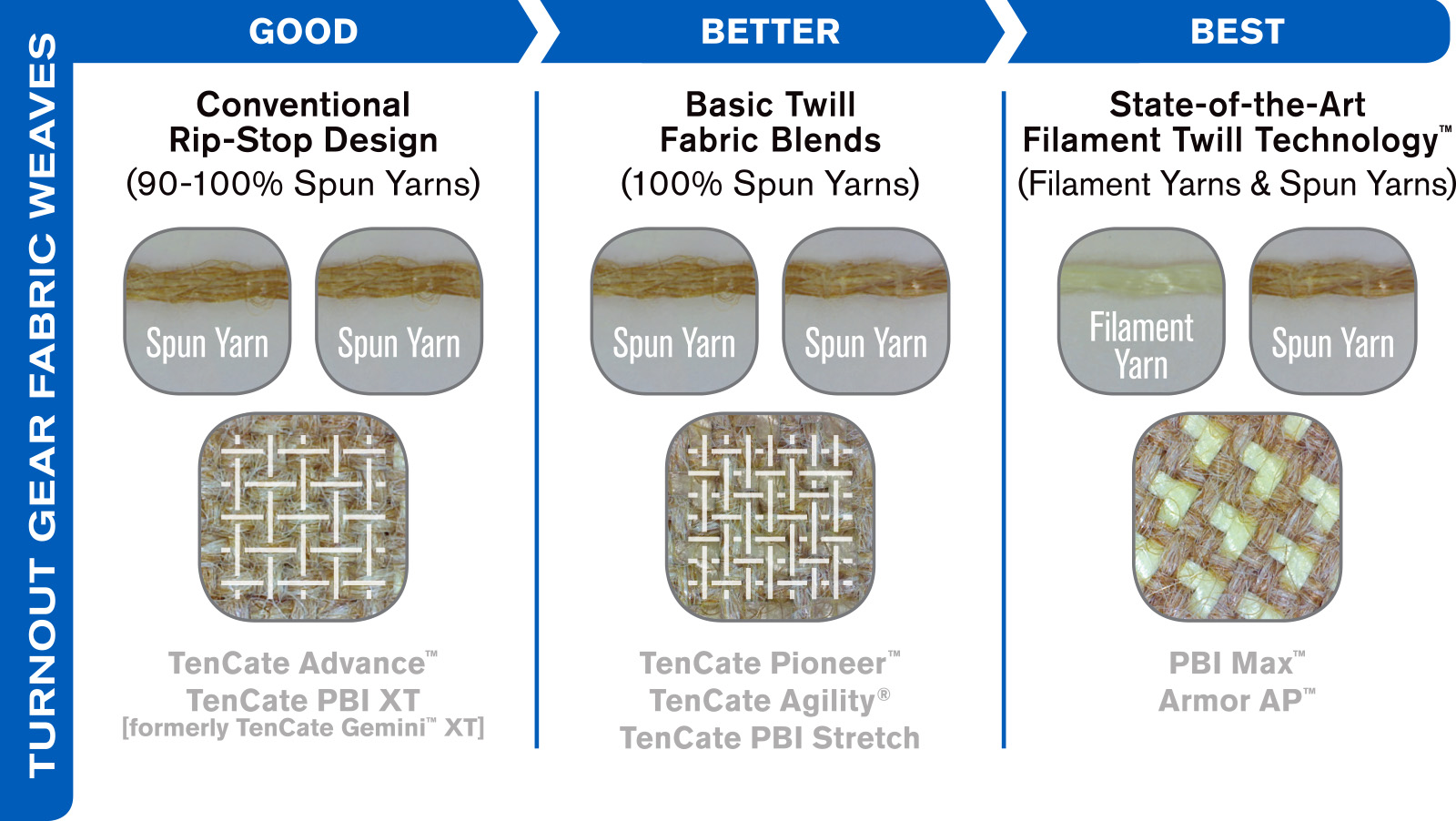

Filament Twill Technology

Filament Twill Technology is a fabric technology patented by Safety Components in 2012. Compared to other fabric technologies like “conventional rip-stop” and “basic twill” designs, Filament Twill fabric designs are lighter and stronger both new and after UV Exposure.